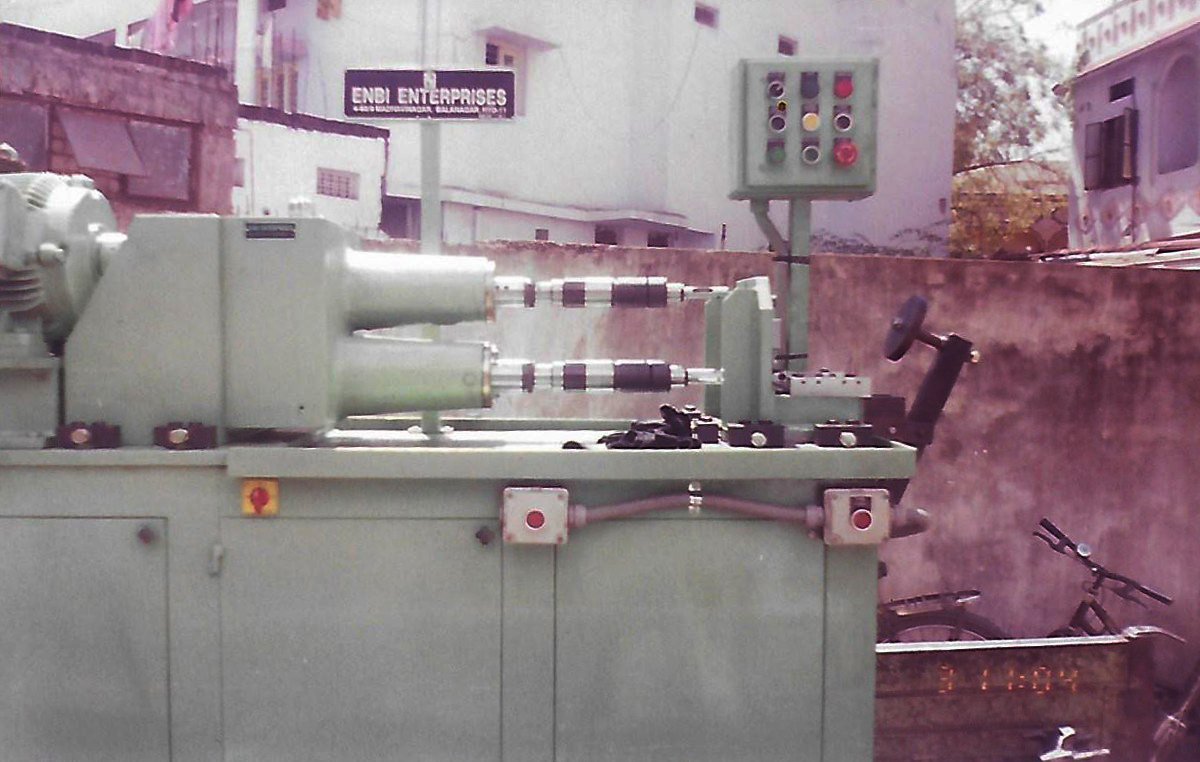

Punching and Extruding SPM

The Punching and Extruding SPM is a specialized machine designed for precise punching and extrusion operations on metal components. It offers high productivity, accuracy, and repeatability, ensuring superior surface finish and dimensional control. Ideal for automotive and engineering industries, this SPM enhances manufacturing efficiency with robust construction and reliable performance.

Key Features –

- High-precision punching and extrusion operations

- Rigid, vibration-free structure for accuracy and durability

- Designed for high production rates and consistent quality

- Hydraulic or pneumatic actuation for smooth, powerful operation

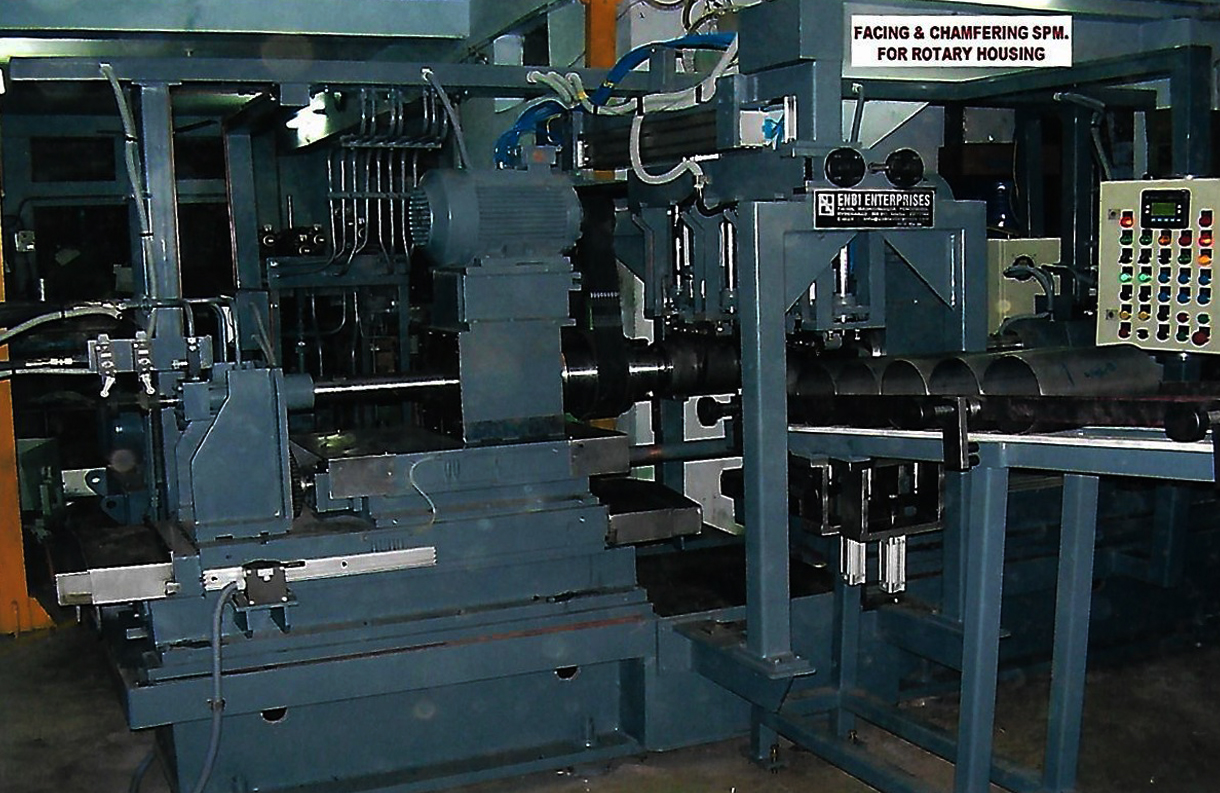

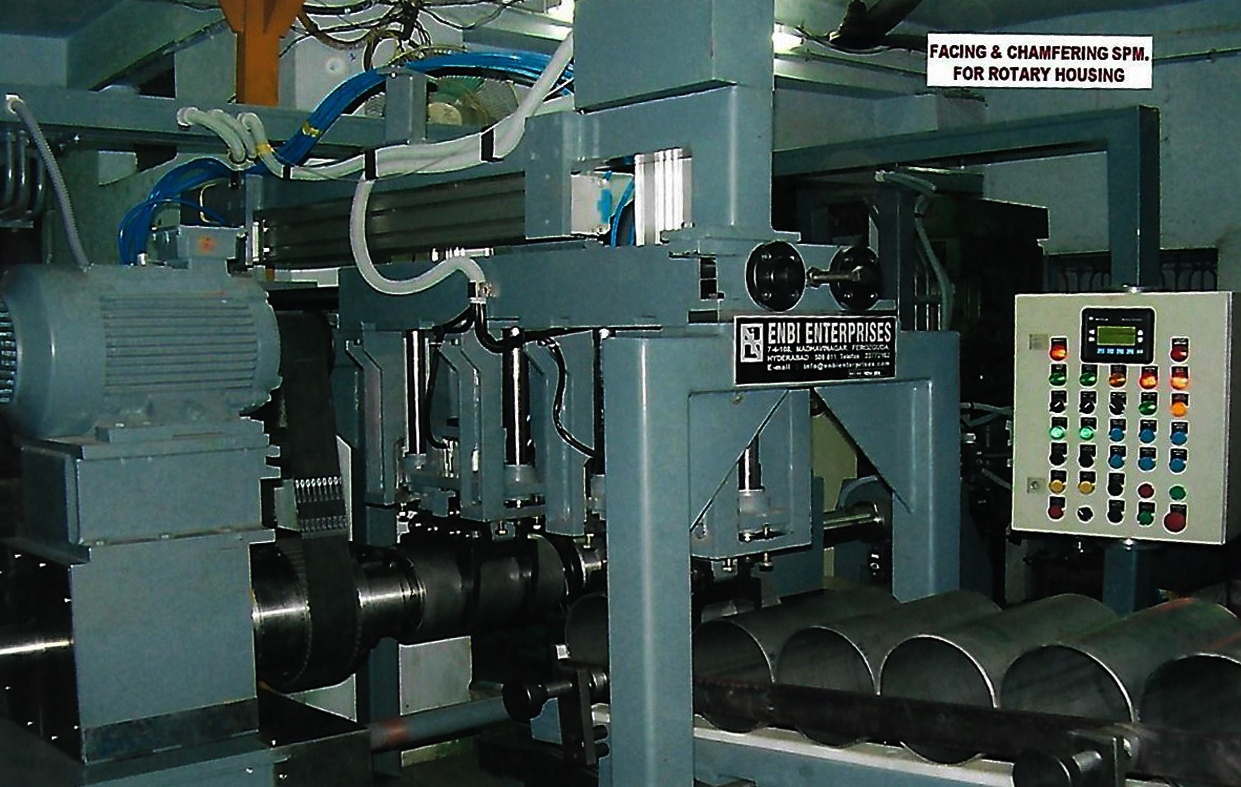

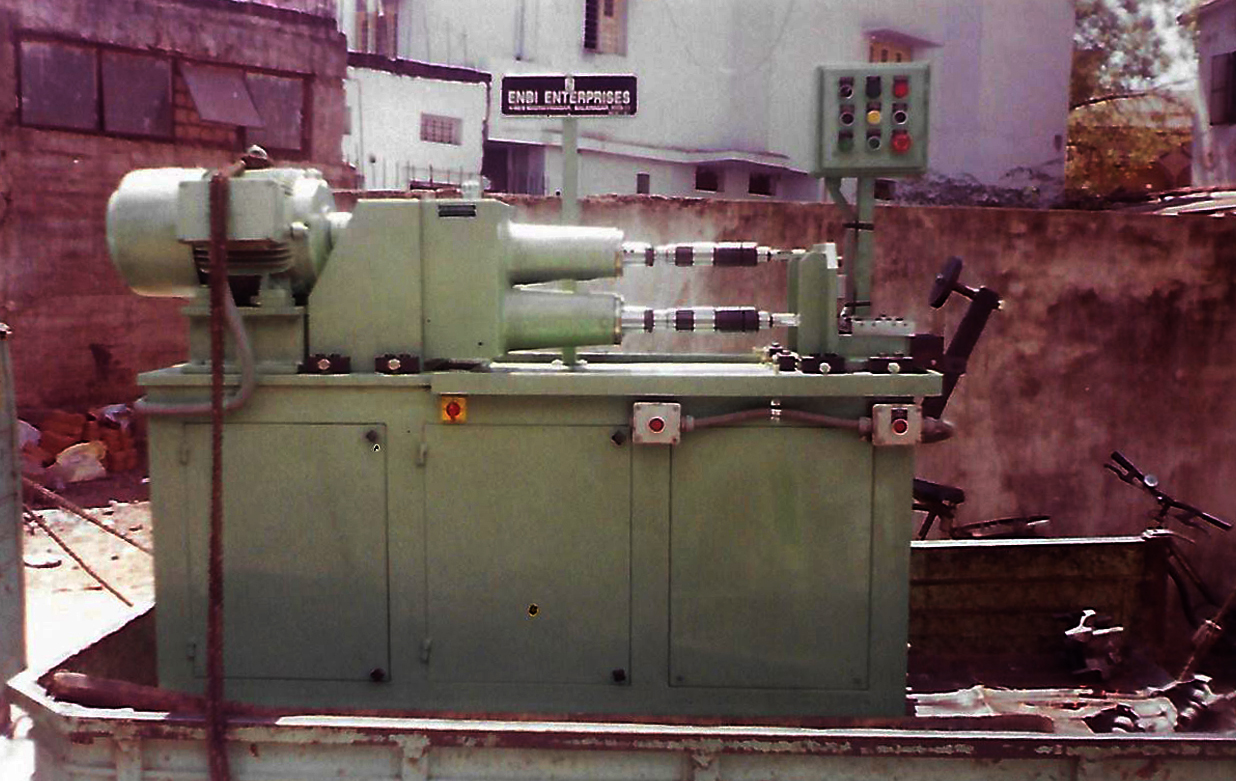

Auto Loader Two-Way Facing and Chamfering SPM

The Auto Loader Two-Way Facing and Chamfering SPM is a high-performance machine engineered for simultaneous facing and chamfering of both ends of shafts or similar components. Equipped with an automatic loading system, it ensures precision, consistency, and high productivity, making it ideal for automotive and engineering manufacturing environments.

Key Features –

- Automatic component loading and unloading for continuous operation

- Simultaneous two-way facing and chamfering for higher output

- High rigidity structure ensuring vibration-free precision machining

- PLC/CNC control for easy operation and process monitoring

- Quick setup and tool change system

- Adjustable feed and speed for different materials

- Superior surface finish and dimensional accuracy

- Compact design for efficient floor space utilization

- Safety interlocks and reliable control system

- Low maintenance, long-life performance

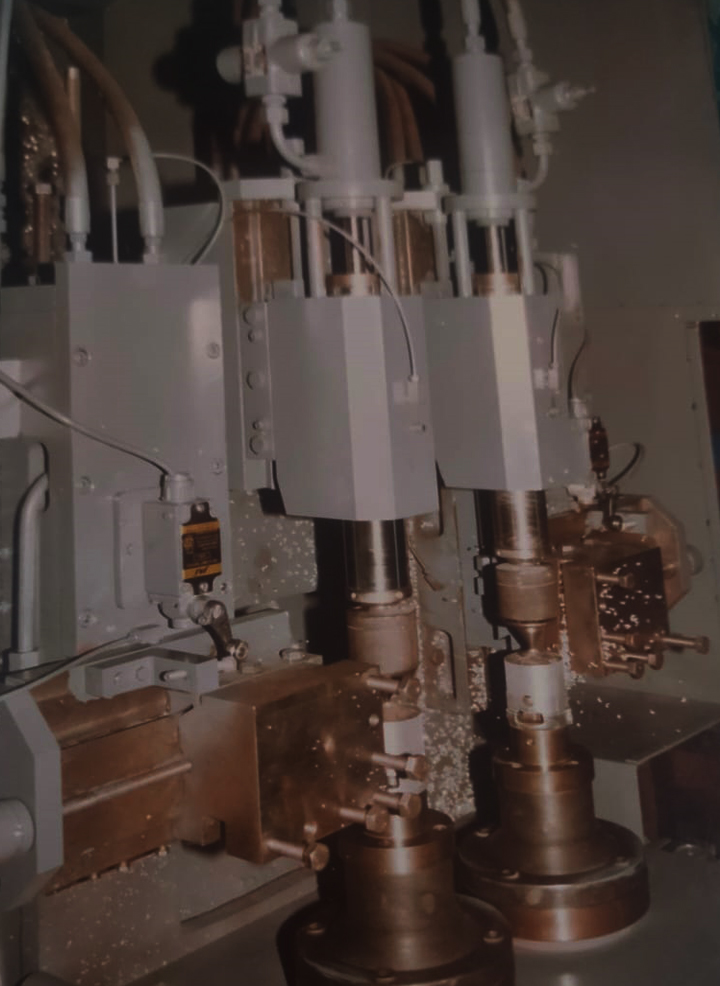

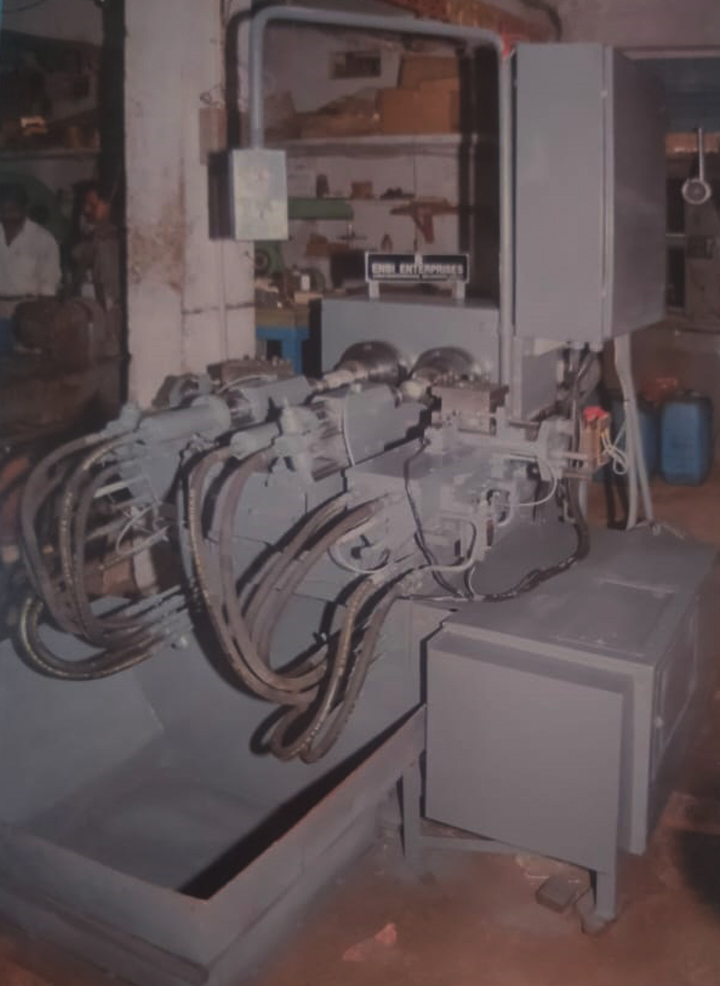

3 Spindle Tapping SPM

The Punching and Extruding SPM is a specialized machine designed for precise punching and extrusion operations on metal components. It offers high productivity, accuracy, and repeatability, ensuring superior surface finish and dimensional control. Ideal for automotive and engineering industries, this SPM enhances manufacturing efficiency with robust construction and reliable performance.

Key Features –

- High-precision punching and extrusion operations

- Rigid, vibration-free structure for accuracy and durability

- Designed for high production rates and consistent quality

- Hydraulic or pneumatic actuation for smooth, powerful operation

- Quick tool change system for minimal downtime

- Adjustable stroke and depth for various component sizes

- PLC/CNC control options for automation and easy operation

- Integrated safety interlocks and operator-friendly interface

- Low maintenance and long service life

- Ideal for automotive, electrical, and engineering applications

Staker Facing SPM

Twin Spindle piston OD Truning SPM