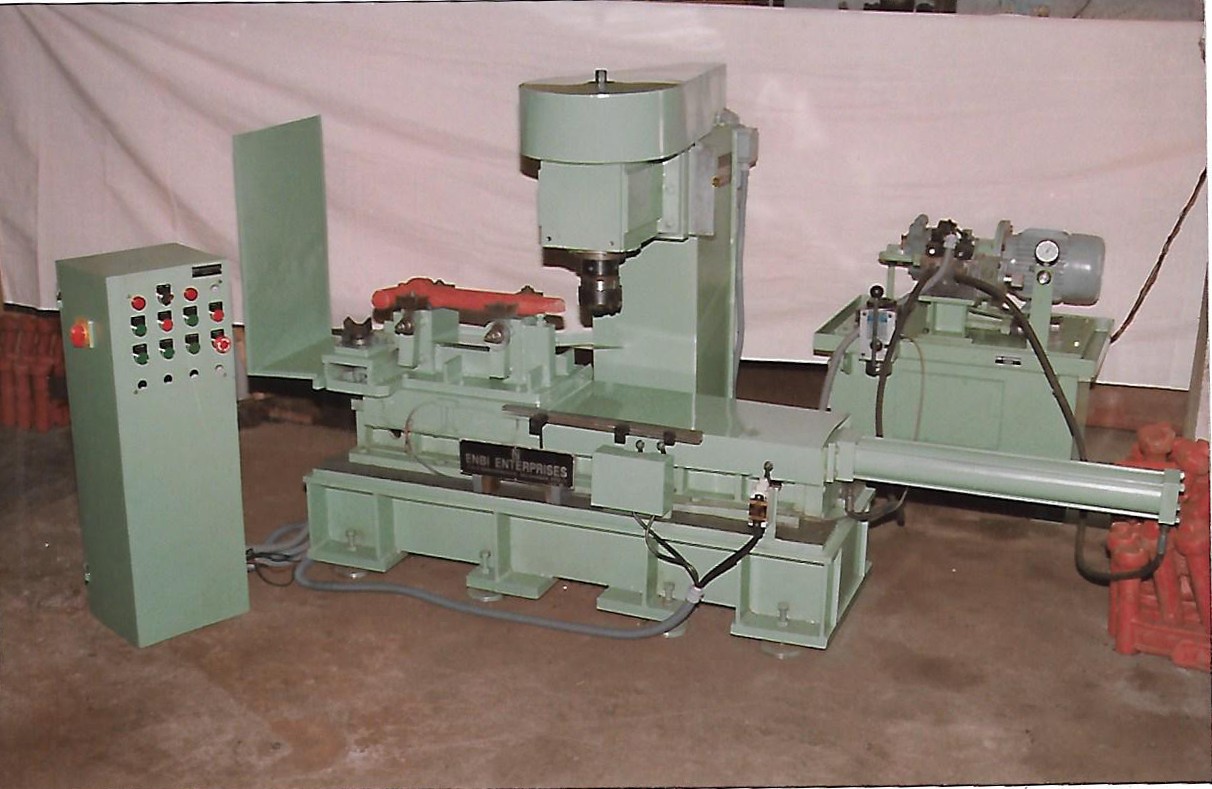

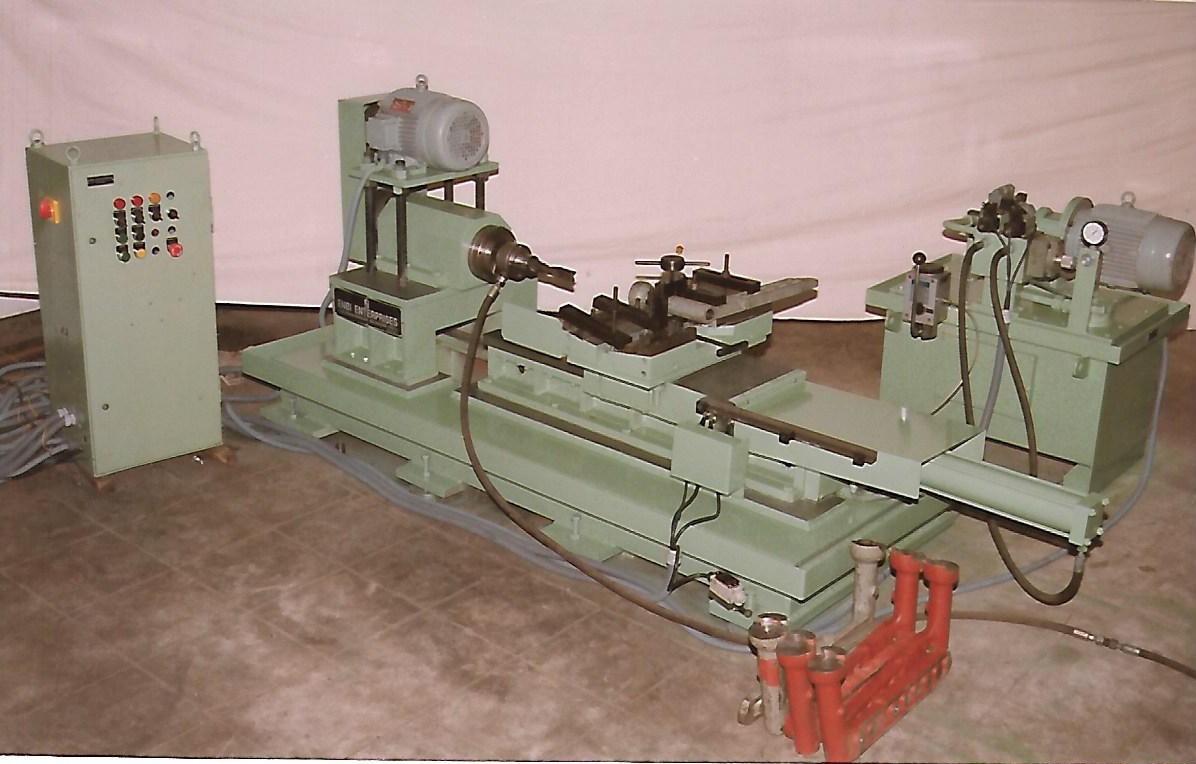

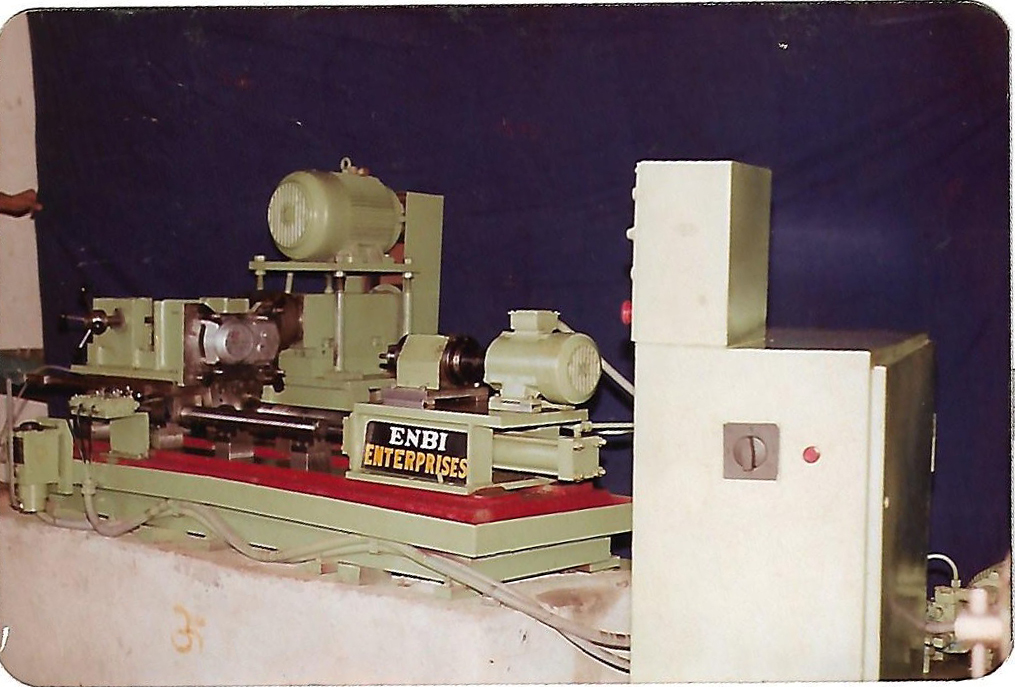

Kick Stator Cover Bore and Facing Machine

The Kick Stator Cover Bore and Facing Machine delivers precise boring and facing for automotive components, ensuring superior accuracy, surface finish, and reliability with semi-automatic or automatic operation for modern manufacturing efficiency.

Key Features –

- High Precision Machining: Ensures tight tolerance control for bore diameter and face flatness.

- Rigid Construction: Fabricated from heavy-duty cast iron or mild steel to minimize vibration and enhance stability.

- Efficient Clamping System: Quick and secure component clamping for faster cycle times and improved productivity.

- Adjustable Tooling Setup: Accommodates different sizes of kick shaft covers with minimal changeover time.

- Smooth Feed Mechanism: Provides uniform cutting feed for superior surface finish.

- Optional CNC/PLC Control: Available with digital control for programmable speed, feed, and depth of cut.

- Coolant System: Integrated coolant supply for improved tool life and reduced thermal distortion.

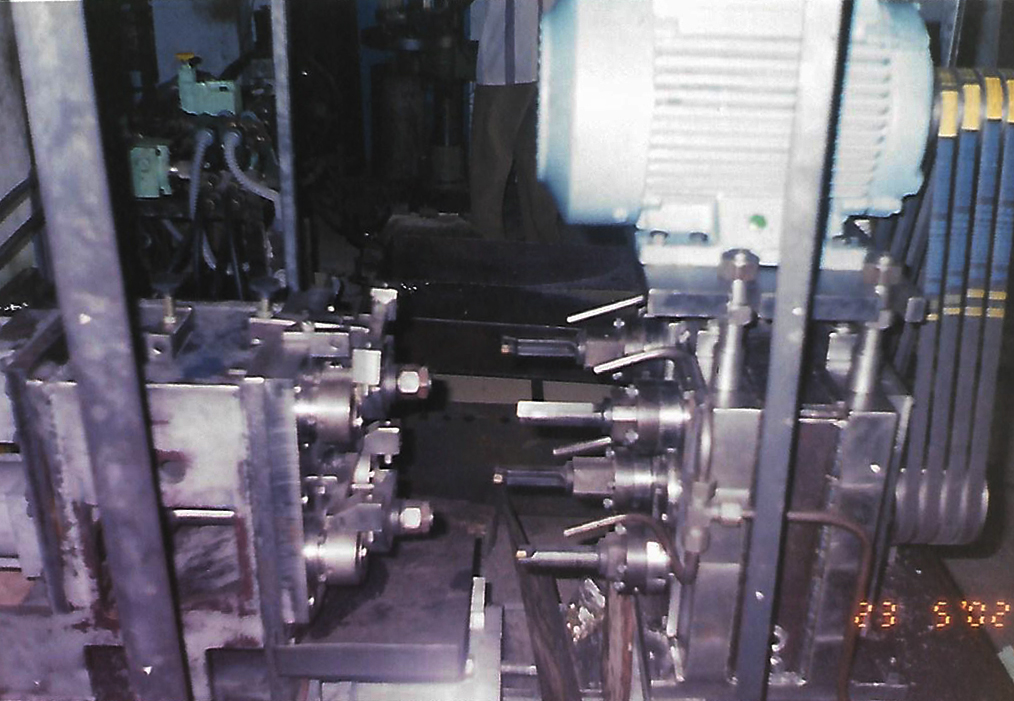

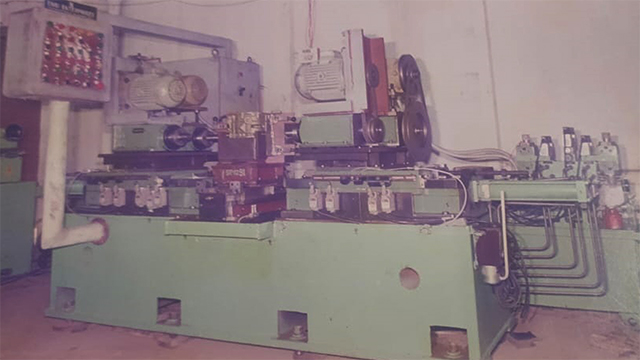

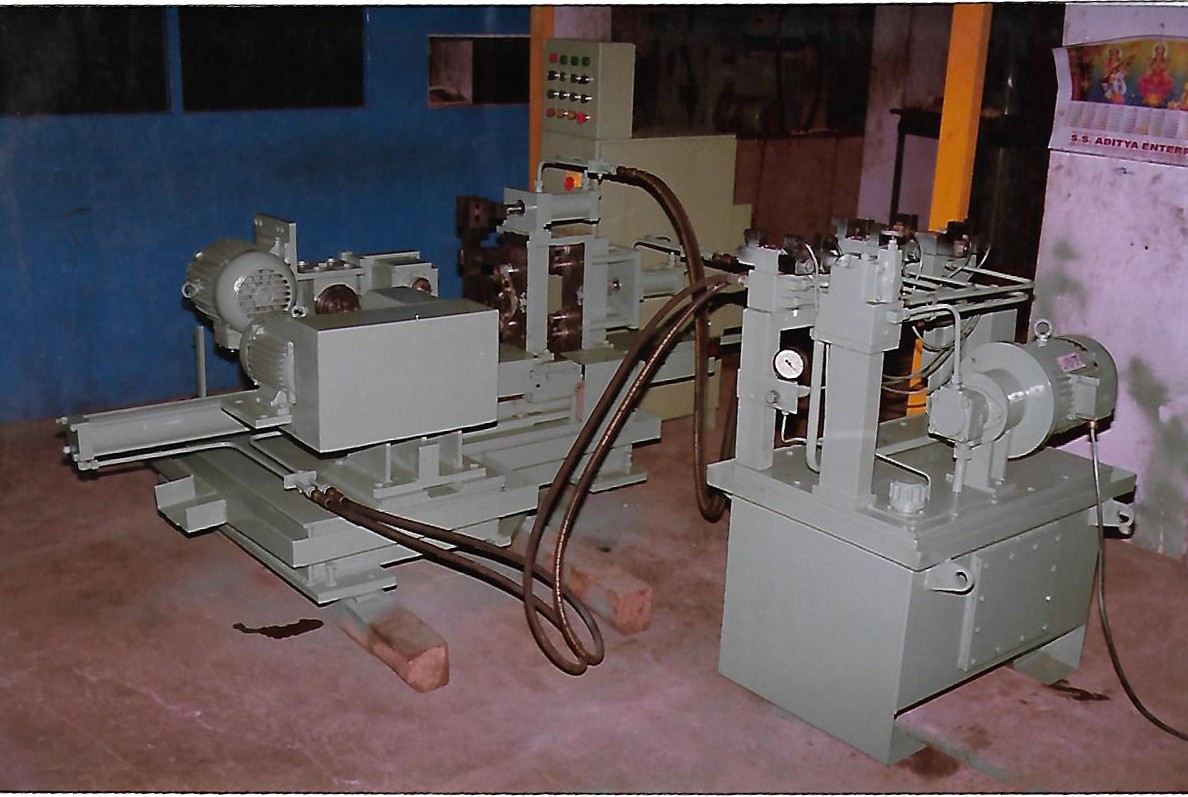

3-Hole Drilling Machine

3-Hole Finish Bore Machine